Force Gauges

Chatillon are force measurement instruments suited for measurement on applications up to 5kN. Chatillon offers force gauges, torque gauges and test stands for force measurement on a wide range of materials. John Chatillon & Sons Company was formed in 1835 in New York, and the year 2010 marked the 175th anniversary of Chatillon products and innovations in force measurement and weighing. The brand covers force gauges, torque gauges and test stands.

Ross Brown Sales Pty Limited supply materials testing machines and force measurement instruments that provide the highest level of performance and capability for production testing, quality control, laboratory testing, research and education. Chatillon and Lloyd Instruments are just some of the world-renowned brands manufactured by AMETEK Sensors, Test & Calibration.

Our force gauges and tensile testers are used to determine the physical and mechanical properties of raw materials and components and ideal for product testing of finished goods such as plastics, packaging, medical devices, electronic components, textiles, metals, composites, paper and more.

What's New

New

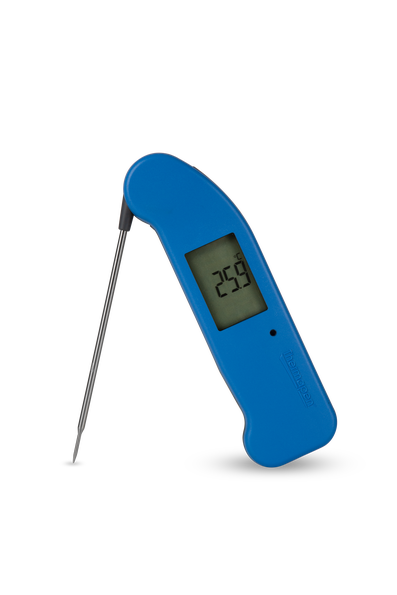

ThermapenOne

The new Thermapen 1 is the ultimate kitchen thermometer for the cook who knows!

- Instant 1 second response time

- Waterproof to IP67

- Auto intelligent backlight

- Biomaster Antimicrobial Technology

- Easy to read rotating display

- British designed and manufactured

- 5-year guarantee

Your Instrumentation Specialists

- sales@rossbrownsales.com.au

- 21 Brookhollow Ave, Norwest, NSW 2153

- PO Box 6345 BHBC, Baulkham Hills, NSW 2153

- 28 000 690 362